NCyclopedia

Multimedia Teachware for CNC Technology

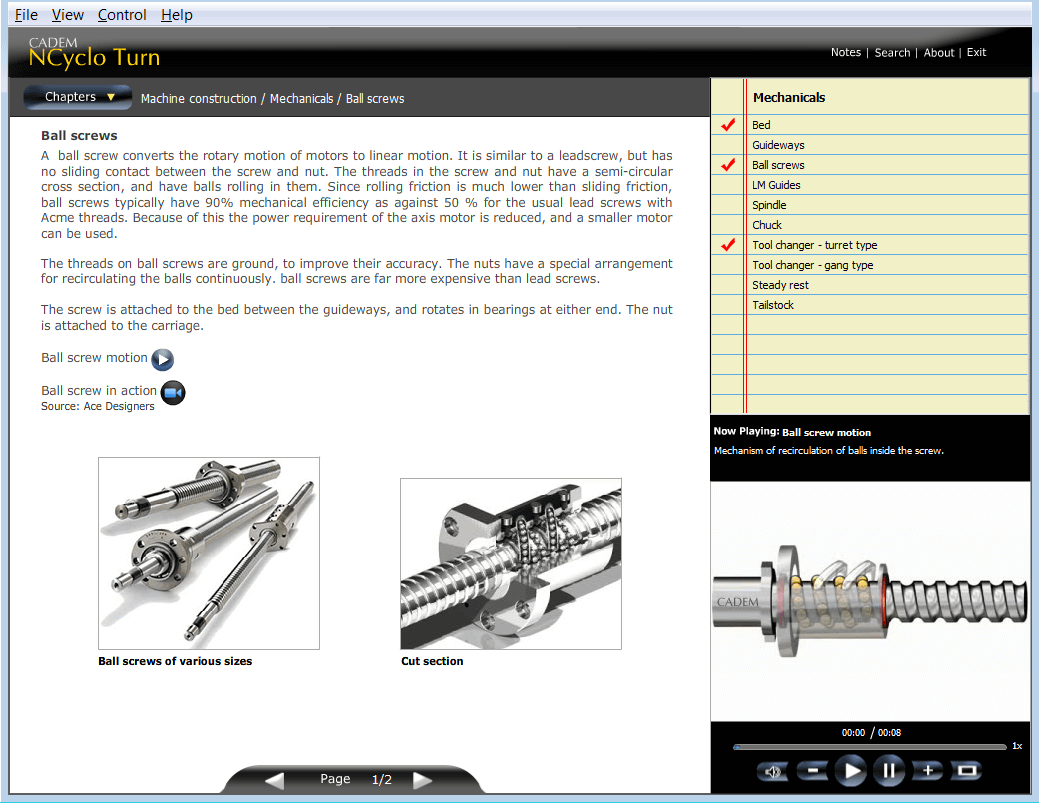

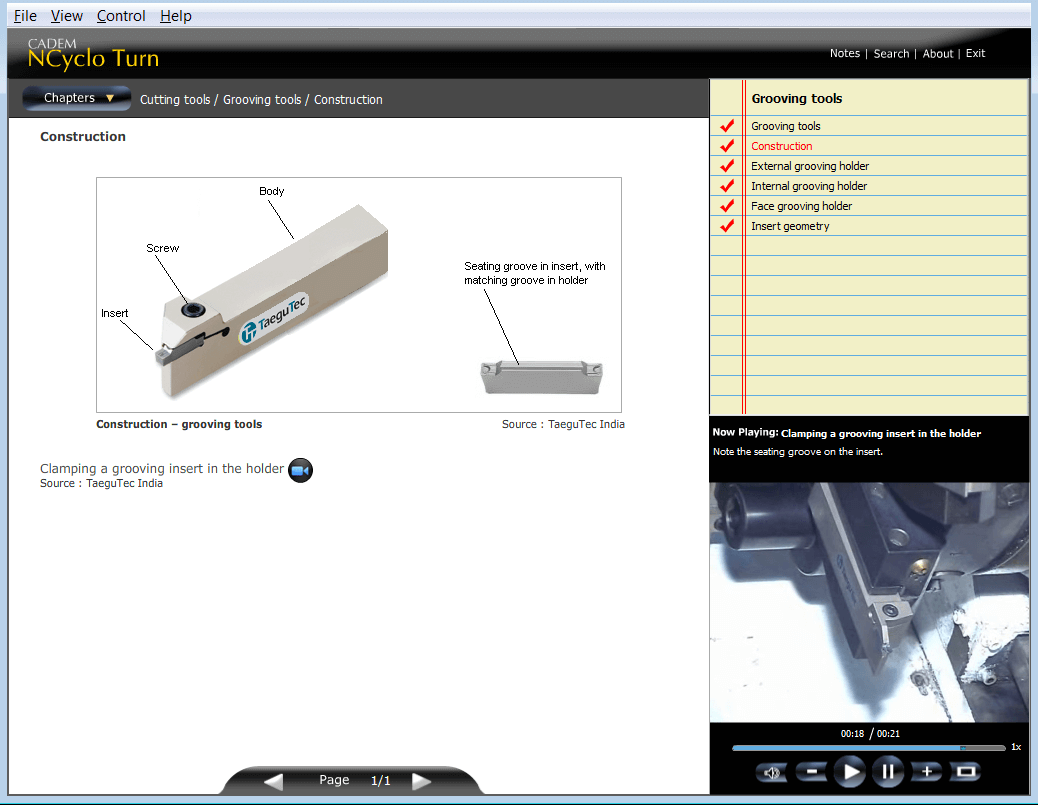

NCyclo Turn and NCyclo Mill speed bring the shop floor into the classroom. They dramatically improve understanding and retention of topics, and speed of learning. The student learns machine construction, machining operations, tooling, work holding and programming. Can be used for teaching by the teacher, or for self-learning by the student.

Features

Comprehensive CNC training software

Eliminates effort of collecting teaching material, Eliminates need for physical demonstration material, Eliminates need to go outside classroom for demonstrations

CNC machining is all about motion. It is impossible to teach using text books. The teacher as a result spends a lot of time making power point presentations. These are however inadequate, and there is still a huge gap between the student’s knowledge and what is required in industry.

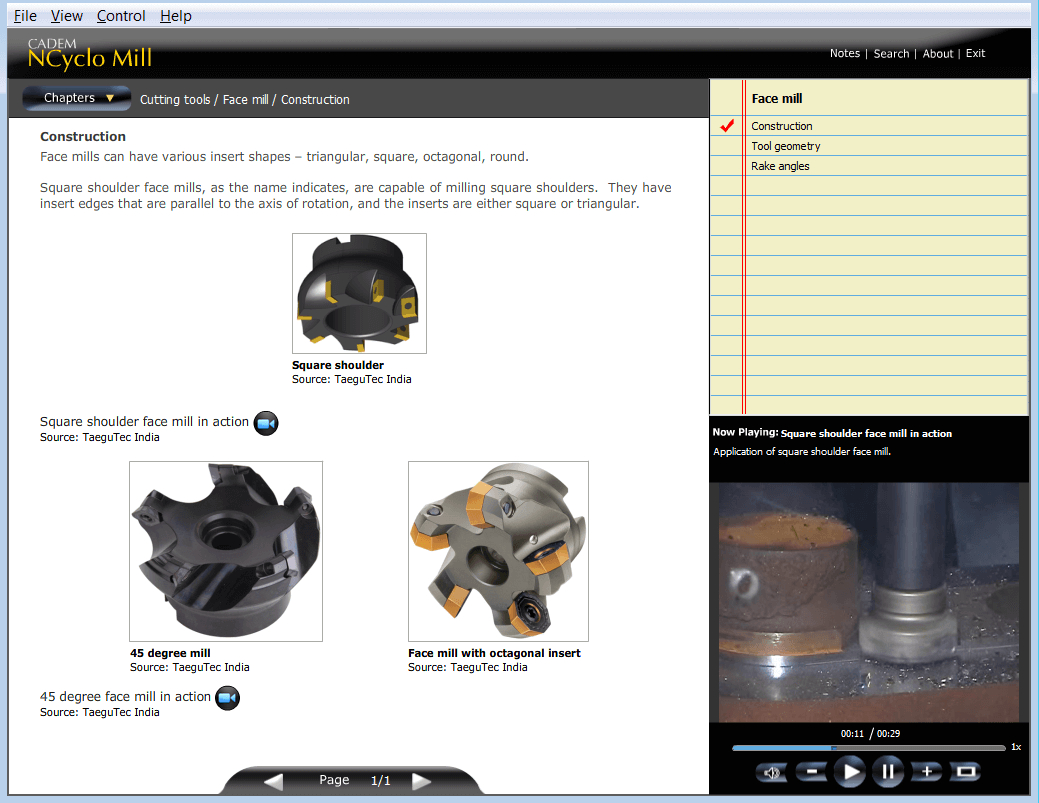

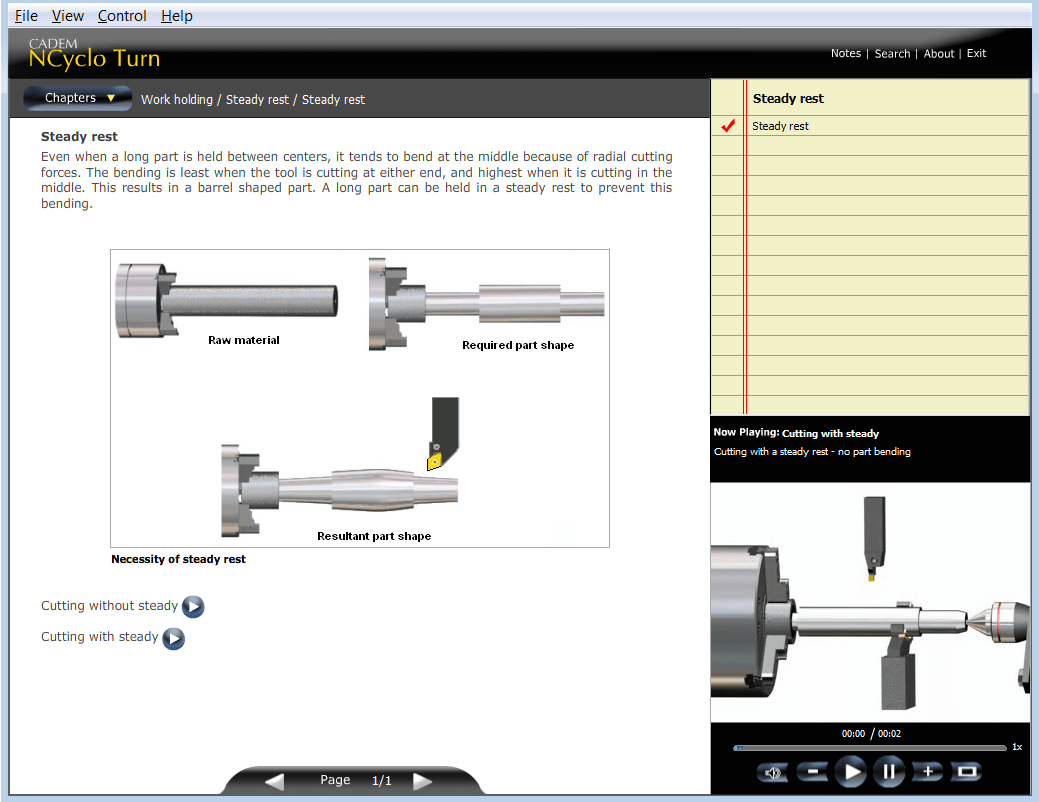

NCyclopedia bridges this gap. It improves understanding and retention of topics. It teaches CNC milling and turning technology in a highly effective manner through videos, animations, pictures and text.

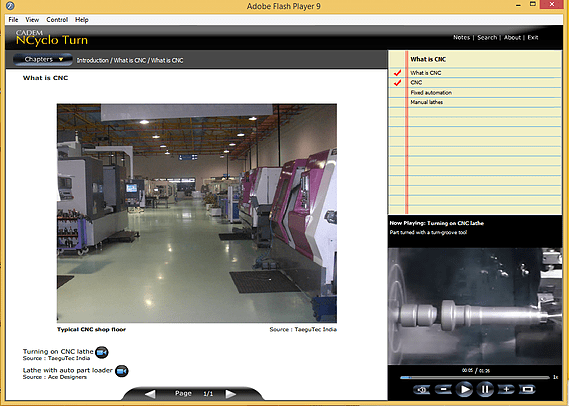

Material is from actual machines, tools and machining situations in industry. Instead of the teacher taking students to the shop floor to show tools and machines, NCyclo brings the shop floor to the classroom.

Who can use NCyclo?

Training centers of industries, for training operators, setters and programmers. CNC and CAD/CAM labs. of Engineering, Diploma and ITI institutes.

Benefits of NCyclo Turn

- Reduces teaching time

- Promotes self-learning

- Modern method of teaching

- Makes the subject interesting

- Learning time < 4 hours

- Improves understanding and retention

Benefits of NCyclo Mill

- Reduces teaching time

- Promotes self-learning

- Modern method of teaching

- Makes the subject interesting

- Learning time < 4 hours

- Improves understanding

- Improves retention of topics

Teaches complex topics

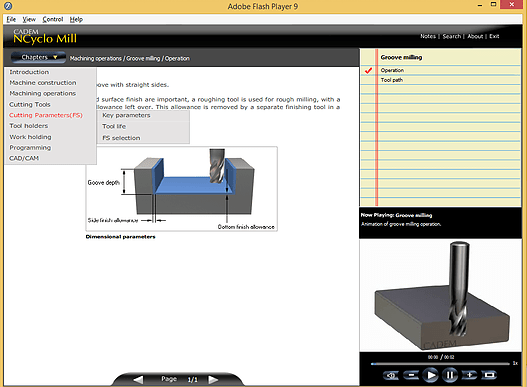

Improves understanding and retention of topics

Brings shop floor into the class room

Teaches variety of operations

Compresses teaching time

Self learning

Watch

Our Customers