seeNC

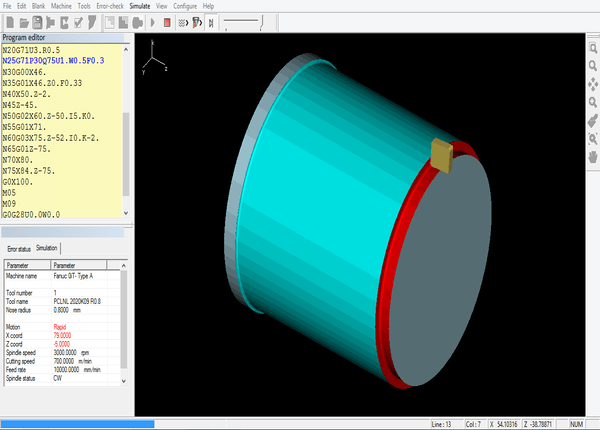

CNC Simulation Software for Programming Training

seeNC Mill and seeNC Turn CNC simulation software enable the student to practise and learn manual CNC programming quickly. The student also learns process planning, tool selection and safety. seeNC supports basic commands, canned cycles and subprograms for a range of popular controllers.

seeNC comes with illustrated programming manuals and workbooks that eliminate the teacher’s job of making teaching notes, presentations and lab programming exercises.

How seeNC Works

Type in the program through a special inbuilt editor.

Software checks the program, displays errors and locations.

Correct the errors in the editor.

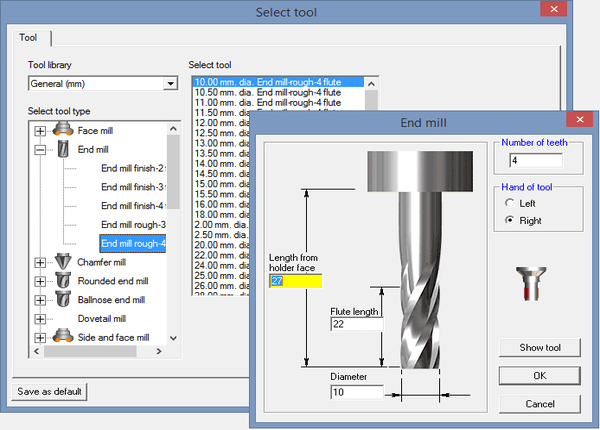

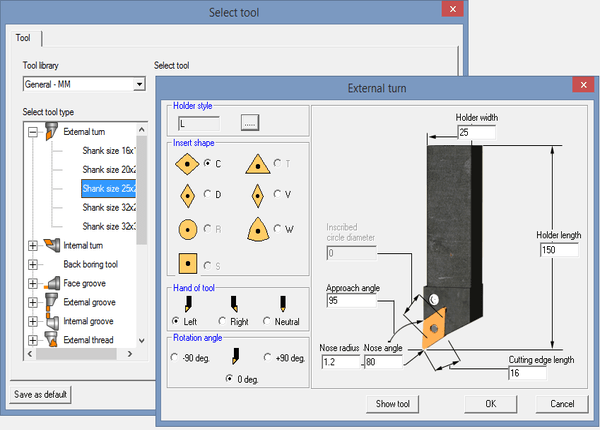

Select cutting tools from industry-standard tools database.

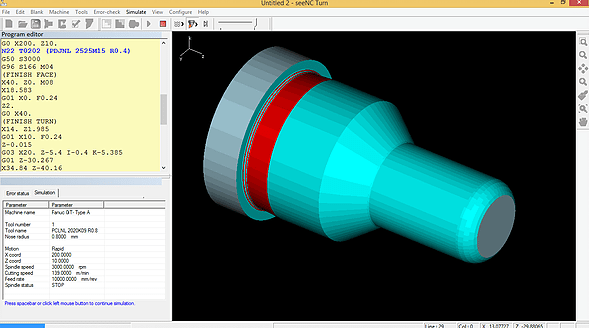

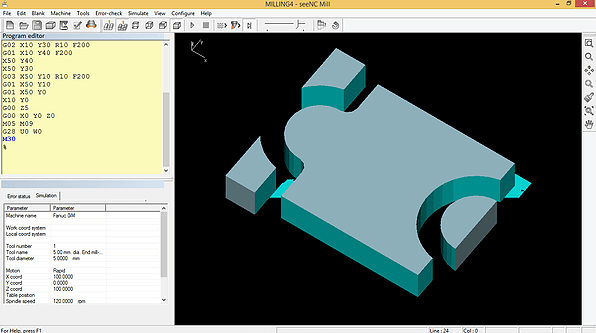

View the tool path simulation with display of tool coordinates.

Correct errors, repeat the syntax check and simulation.

CNC simulation software for learning programming for CNC lathe. Supports Fanuc, Siemens, Fagor, Mitsubishi controls.

Who can use seeNC?

Training centers of industries, for training CNC operators, setters and programmers. CNC and CAD/CAM labs. of Engineering, Diploma and ITI institutes

Benefits of seeNC Turn

- Speeds up learning

- Reduces load on faculty

- Makes learning interesting

- Forces learning of safety aspects

- Forces learning of safety aspects

- Add more exercises in lab time

Benefits of seeNC Mill

- Speeds up learning

- Reduces load on faculty

- Makes learning interesting

- Forces learning of safety aspects

- Forces learning of safety aspects

- Add more exercises in lab time

Supports standard tooling

Edit tools

Collision detection

Simulation turning

Simulation milling

Watch

Our Customers