CAPSmill

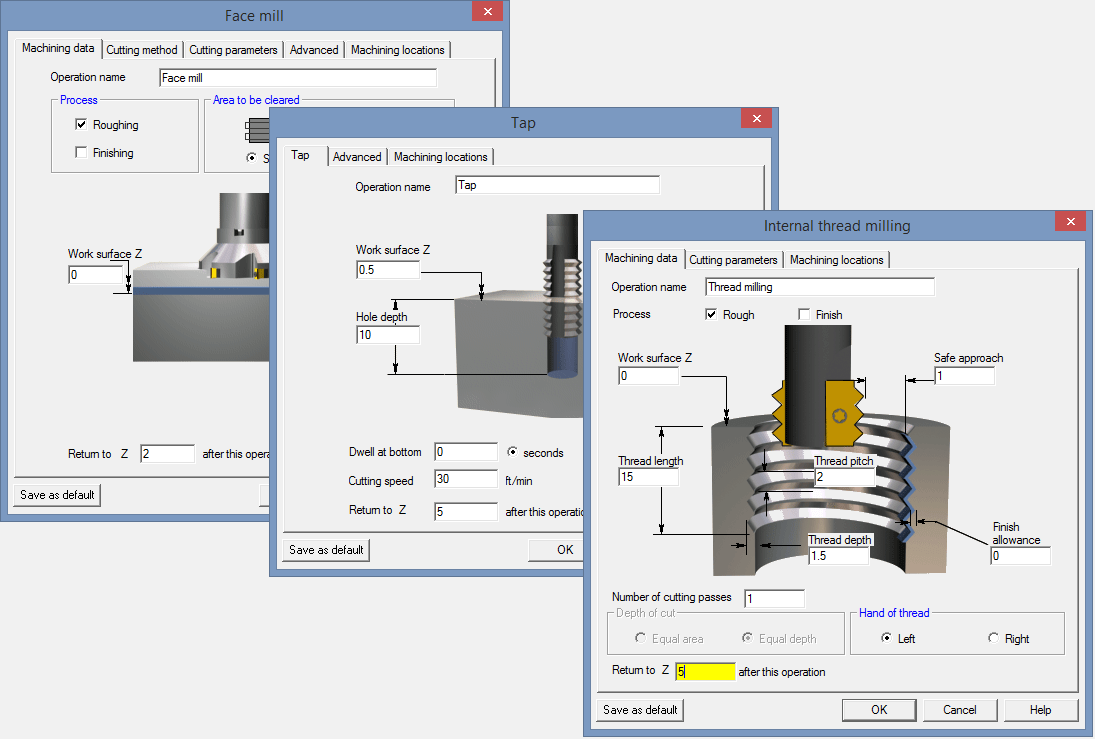

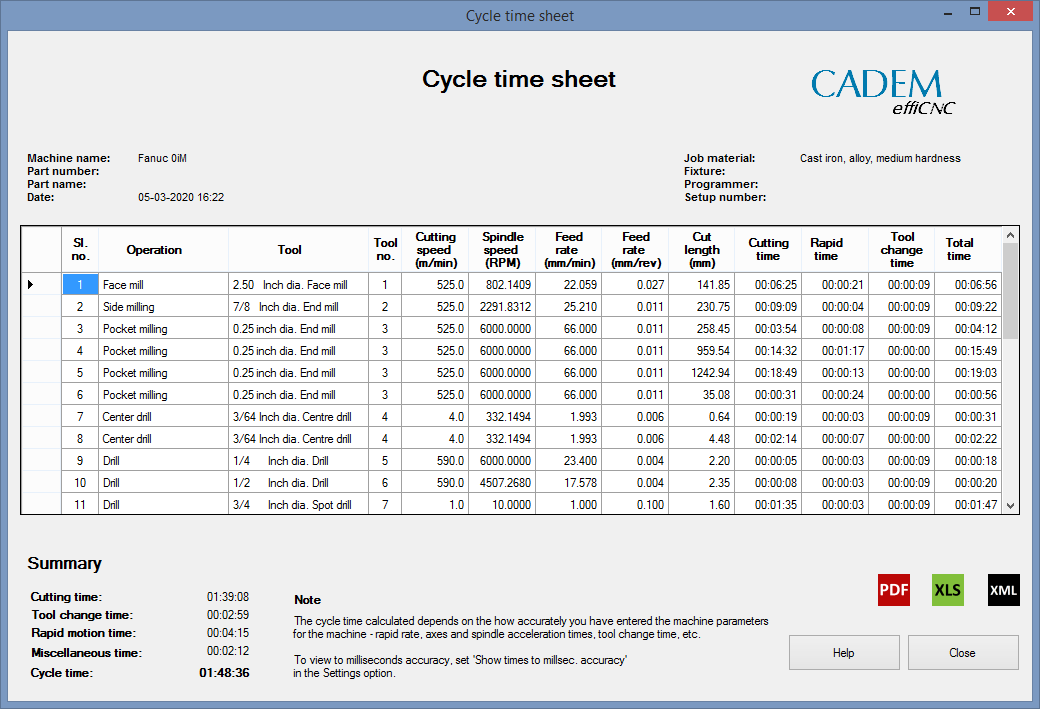

CAD/CAM software for CNC Machining centers

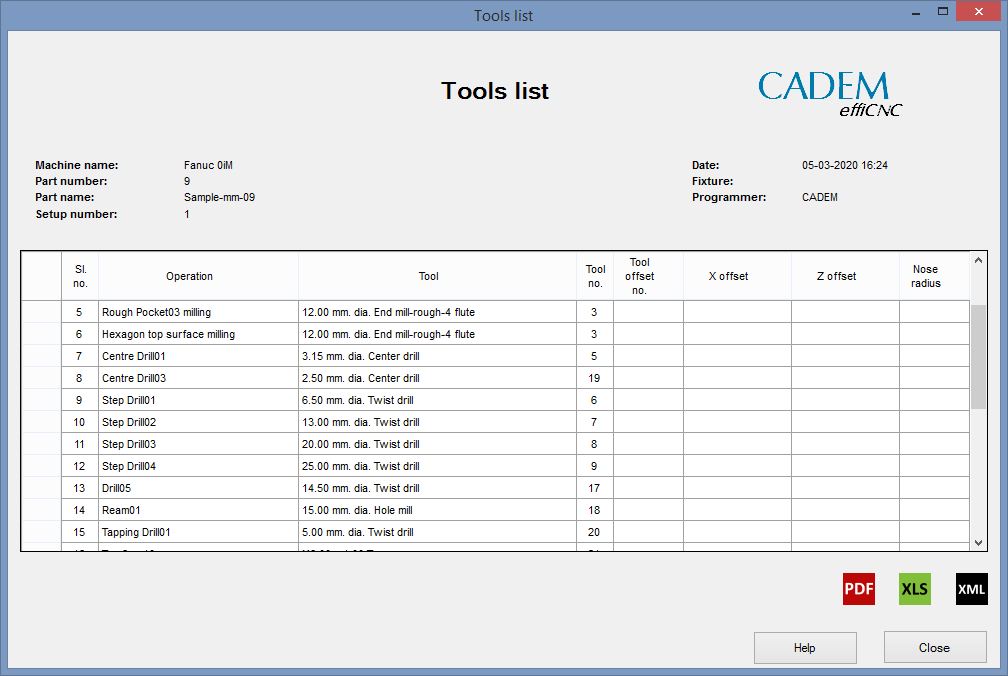

CAD/CAM software to reduce cycle time, get first-time right programs with zero editing. Print tools list, cycle time and process sheet, spindle power graph.

Features

Automatic safe path logic zero collisions.

The program generated by CAPSmill can be loaded on the machine and cut right away, without any editing.

There is no machine downtime for program checking through single block and dry run.

Cycle time is drastically reduced by automatic cutting parameters selection.

Automatic Cutter radius compensation and gouge prevention ensure that you can take on parts with complex geometries, with no rejections caused by contour inaccuracies.

Testimonials

Rolex Engineers

Chinchwad, Pune

Very effective and easy Software. Doesn't need any skilled CNC Programmer any more. part cost has reduced significantly, this software help us to quote accurately.

Pradeep Khare

Pune

Making NC programme is easy. CAPSturn is a easy to learn which can be learnt very easily. Wide variety of operation always come handy and it gets the job done without any tears.