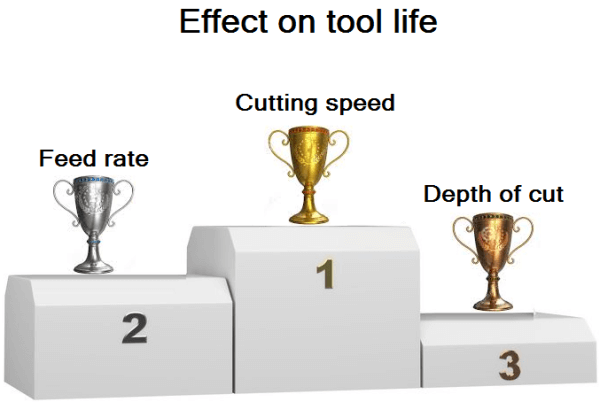

Which cutting parameter has the highest effect on tool life ?

All cutting parameters do not have the same effect on tool life. Cutting speed has the highest effect on tool life. Feed rate has a much smaller effect. Depth of cut has almost no effect.

Cutting speed increase of 20% leads to tool life reduction of 50 %.

Cutting speed increase of 50% leads to tool life reduction of 80 %.

Action point

To reduce cycle time, increase the depth of cut first, to the maximum that the tool or insert can take. Next increase the feed rate. If possible, avoid increasing the cutting sped. Use the cutting speed recommended by the tool manufacturer.

Etc

The ‘Messes’ of South India – how did they get their name ?

You’ll find a lot of small eateries called Messes in South India, that are simple places where you go for the food. They don’t serve anything other than food and water – no juices, no sweets, no desserts, and of course no booze. I’ve seen this term used for eating areas in the military or in schools or colleges, and wondered what the connection was between these.

The word Mess originated from the Latin Missum (something put on the table), changed to the Old French Mes (Portion of Food) and then changed finally to the to the English Mess in the 16th century. Mess meant a group of people who regularly ate together, and the place where they ate was the Mess Hall. Mess Hall finally got shortened to Mess.

I only recently figured out that messes are typically in localities with a lot of single people who come there to eat every day – working people who do not cook at home. And it’s usually the same set of people coming to eat at every meal. Hence calling them messes is perfectly logical. If you want simple, cheap and authentic local food in any place, going to any place called a Mess guarantees this.

| Interested in a Plug-and-play Industry 4.0 system ? See LEANworx, from our group company. |  |