What is 5S in LEAN manufacturing ?

5S in LEAN manufacturing is a method of organizing the workplace to improve efficiency, and is a foundation of TPM. The term comes from the 5 Japanese words seiri, seiton, seiso, seiketsu, and shitsuke. In English, these words are translated as Sort, Straighten, Shine, Standardize and Sustain . 5S enables the work space to be organized to improve efficiency – by identifying and storing the items used, and maintaining the area and items.

Sort

Make the workplace more efficient by removing all obstacles and unnecessary items. Remove all tools and parts that are not in use, and remove all waste material.

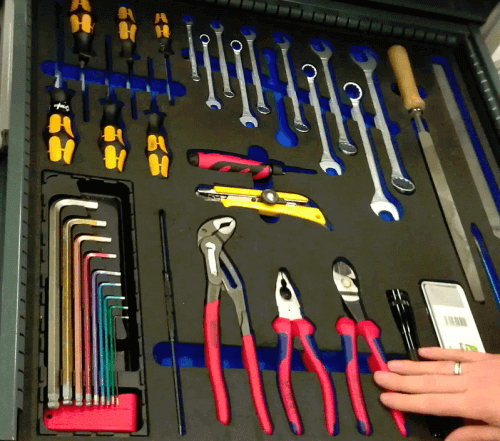

Straighten

Arrange all necessary tools, equipment and parts so that they can be easily selected for use. Prevent loss of time by ensuring that all tools and equipment are within reach. Place components by their use, those frequently used being closest to the work place.

Shine

Clean the workplace daily or at a set frequency. Inspect the workplace while cleaning, prevent deterioration of equipment. Keep the workplace clean and pleasant to work in. Even a person unfamiliar with the workplace must be able to detect any problems within 50 feet in 5 sec.

Standardize

Standardize all processes in the work area. Everything in its right place, every process has a standard. Standardize color coding of usable items People must be aware of the processes Sustain

Do all this autonomously, without being told. Perform regular audits. Follow the process, but also be open to improvement Action point A surprising amount of time is wasted on the shop floor searching for things (like the example in this post ) and navigating obstacles.

The principles of 5S in LEAN manufacturing are simple, can yield huge benefits if implemented, and can be implemented in any size of shop floor.

Etc

My Misal Pav mistake

Driving from Satara to Pune a few weeks ago, I stopped in a town called Lonand for a breakfast of Misal Pav. This is a popular breakfast dish in Maharashtra. Misal means ‘mixture’ in Marathi, and Pav is a shaped cubical bread. The Misal is sprouted green gram boiled and cooked with fried onions and masala. The Misal Pav is served with raw onions and fried chillies.

The Misal is a water-less mix of things, and not very spicy. What really converts this into a propellant that can put you in geosynchronous orbit is something called ‘Cut’. Cut is water boiled with a bunch of spices, predominantly chilly powder. It is the liquid layer on top of the Misal. As you tuck into your misal pav and the level of the misal goes down, the waiter periodically arrives with a little container of Cut to replenish it and keep the spice level high. I have no idea how it got its name, but I guess it’s because it can cut through your stomach wall.

I, with tears in my eyes because of the spice level, of course refused all further offerings of Cut. Through my tears I did notice that the guy at the next table asked for three more servings of the Cut. Lucky guy, with a cast iron stomach. Sadly for me, my tolerance level for spice is rather low. I like high spice and can eat it, but my alimentary canal (particularly the last part) reminds me of my folly, for a few days after.

A good bit of the Misal pav is actually of Portugese origin. The name Pav is from Pao, the Portugese word for bread. Chillies came to India with the Portugese explorer Vasco da Gama.

| Interested in a Plug-and-play Industry 4.0 system ? See LEANworx, from our group company. |  |