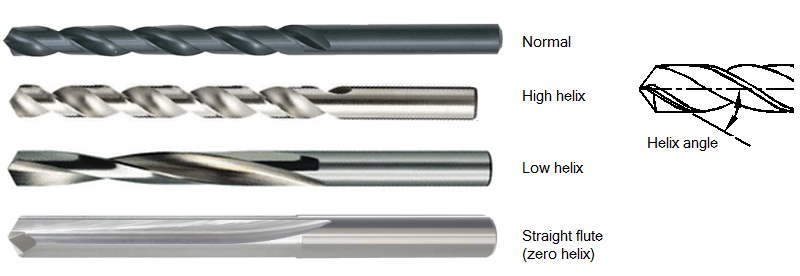

Helix angle in drill – how it affects cutting, and applications

The helix angle in drill has a big difference on the cutting efficiency. The higher the drill helix angle, the greater the force pushing chips axially out of the hole. However, the higher the drill helix angle, the smaller the cross sectional area of the drill and the weaker it is.

| DRILL TYPE | DRILL HELIX ANGLE | APPLICATION |

| High helix angle (alias fast spiral drill) | 40 | Used for high feed rate, low cutting speed. On soft non- ferrous metals like brass, aluminum, magnesium, zinc, plastics. |

| Standard helix angle | 30 | Has optimal chip ejection and strength of drill cross section. Most widely used. |

| Low helix angle | 12 | Used with high spindle speeds on (alias slow spiral drill) hard to drill materials,,because it has high cross section strength. |

| Straight drill | 0 | Used on low tensile strength materials like copper and brass and on sheet metal, because it does not have a tendency to ‘pull in’ the material (and thereby bend it, if it is a sheet or of thin cross section). |

Action point

The general rule is that the deeper the hole, the higher the helix angle must be, for better chip removal. The higher the cutting forces (harder, stronger material), the lower the helix angle must be.

Transform production and profits dramatically, in just a few months.

With a CNC machine monitoring system.

Etc

Sugarcane juice machines across India

As I travel across the country, I come across a fascinating variety of machines that are used to make sugar cane juice. They all have one thing in common, which is that there are two rotating rollers between which the cane is pushed. How you rotate the rollers differs – could be driven by hand, by a bullock, a small petrol engine, or if you want to be really boring, by an electric motor. My favourite machine is the wooden bullock driven one, and the next is the wooden human driven one.

The recipe for the juice is very simple: Crush the cane with ginger and lime, filter through a sieve, and serve. Tastes like heaven, but probably has the bacteria of hell, considering the way it’s made. I, like the average Indian, have a cast iron stomach (or maybe something more corrosion-resistant, like stainless steel or titanium). The joys of drinking roadside juice far outweigh the very faint possibility of coming down with some dire stomach problem. Here’s a video of the process. For those who are very particular about the hygiene, there are of course the boring sanitized sugarcane juice places with boring sanitized machines, that have sprouted up in cities.

Pic. source: http://canefresh.sharepoint.com